PRODUCTS

Single-crystal furnace transformation technical program

I、Technical program

The solution we are currently adopting is to change the bottom and exhaust

structure, increase the length of the auxiliary chamber (increase the isolation

length of the single ingot, lengthen the corresponding seed crystal rope), and

increase the heating power at the bottom, add a bottom heater (with copper and

water-cooled cables, etc.), add a water-cooled heat shield, and design a

26-inch oxygen-lowering field.There are several main advantages:

A、Changing the side exhaust to the bottom exhaust, effectively improving the easy clogging of the exhaust pipe during successive pulling processes, and making a few processes simple and easy;

B、Add the bottom heating power and bottom heater. The oxygenation field can effectively improve the oxygen donor problem in the crystal head, and the head oxygen content is lower than 16ppma.

C、The thermal field structure is organically integrated with the water-cooled screen. The thermal field gradient is suitable, which is favorable for crystal formation, enhances the crystal growth rate, effectively reduces the equal diameter time, and improves the yield;

The above schemes elaborate on their respective characteristics. In addition to changing and adding hardware, the corresponding production process will be changed accordingly, from the technique of one furnace with one rod to the technique of one furnace with multiple rods. Only integrating the two techniques can achieve the purpose of improving product quality and production capacity and reducing production costs.

The modified 95-model single-crystal furnace owns the following advantages:

1、The isothermal pulling speed is greater than 1.4mm/min (average pulling speed);

2、Quality improvement: The oxygen content of the single crystal head is less than 16ppma, which can effectively eliminate the effects of concentric circles, black chips and other factors affecting conversion efficiency;

3、Combining the cost advantages of the above two points, the square non-silicon cost can be controlled around 60 yuan/kg (converted weight);

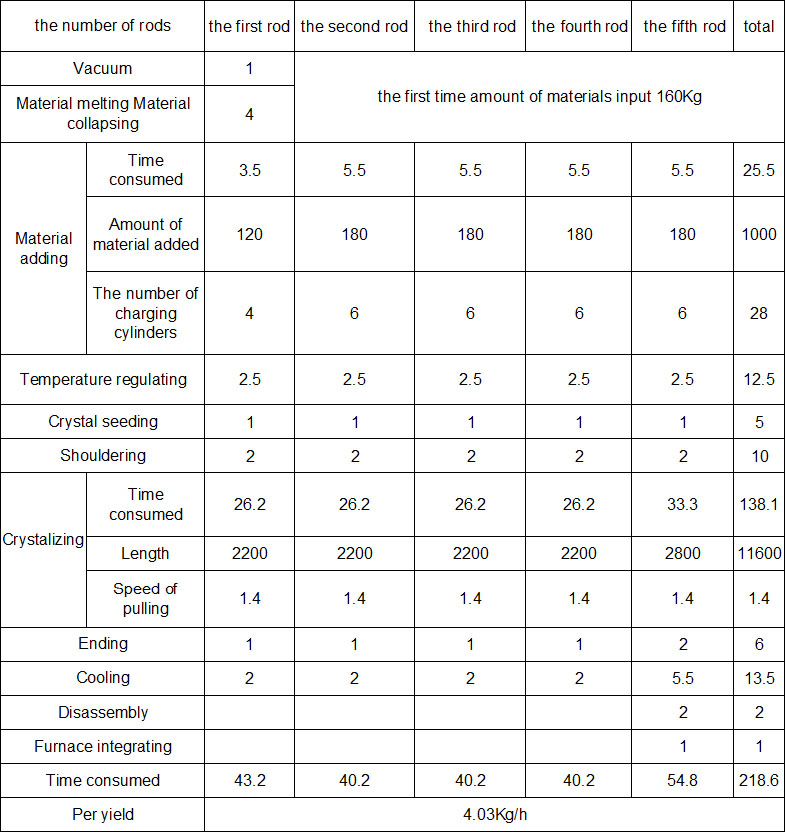

4、The actual crystal pulling process is as follows (excluding

unsuccessful lead and broken edges):

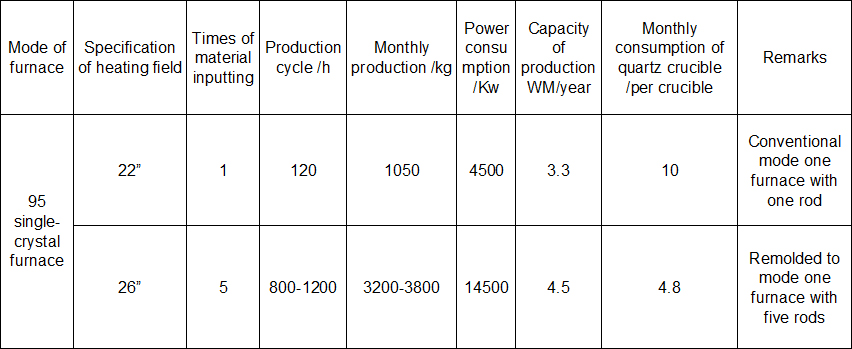

II、Comparison of data before and after remolded (Note: the new 95-model furnaces are manufactured according to the technical standards after the transformation):

Jiangyin Lvyuan Environmental Protection Technology Co., Ltd.ADD:No.1018, Riverside south road, Jiangyin City, Jiangsu Province,ChinaTEL:+86 510-86631330 E-mail:82594041@qq.com |

ABOUT

ABOUT

About us Culture Organization structure |

PRODUCTS

PRODUCTS

Toothpaste、ointment、cosmetic paste completing equipment Metallurgical、environmental protection、power non-standard equipment Stainless steel products Pressure vessel Construction machinery series |

NEWS

NEWS

Company news Industry dynamics |

CONTACT

CONTACT

Contact us Message |

Copyright  2019-2029 en.jylyhb.com. All rights reserved. 2019-2029 en.jylyhb.com. All rights reserved.

|